Taco LOFlo System from N.H. Yates

Designers and engineers are constantly looking for new ways to make heating and cooling systems more efficient and environmentally friendly. The people at Taco created their LOFlo System with the intention of setting a new standard in design and performance for a Green Energy hydronic regulator, and, they’ve done just that. The award-winning Taco LOFlo System is a hydronic heating and cooling regulator that significantly reduces the flow of water in hydronic heating and cooling systems. Typically used in radiant panel (ceiling, wall, or floor) and chilled beam (passive and active) applications, the Taco LOFlo System significantly reduces pump flows and pipe sizes which equates to reduced energy consumption and lower installation costs. In addition, the LOFlo System also allows for precise control of supply water to the terminal, and precise control of room temperatures.

How Does the Taco LOFlo System Work?

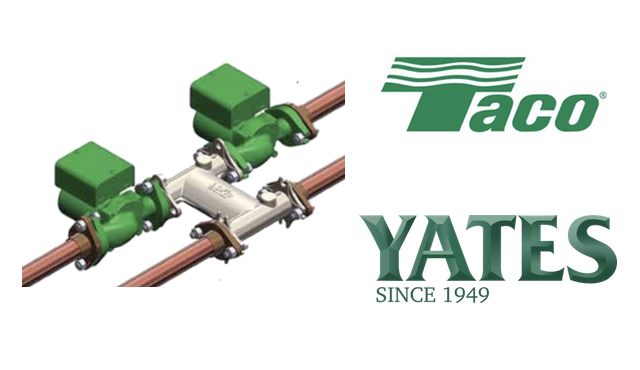

The LOFlo System is a simple, factory-ready package that allows users to control each individual zone at the lowest possible flow rate by maintaining the highest possible water supply temperature when cooling and lowest temperatures when heating. The LOFlo unit consists of a single cast header which functions as a hydraulic separator with two small circulators attached. One of the circulators is for the primary system flow and the other injection circulator that adjusts to precisely match the required load on a given zone. After installation, in a modern radiant system or chilled beam system, only two pipes are needed to control and maximize the flow rate. Flow rates are able to be reduced without the use of control valves, balancing valves, or piping loses to overcome. Instead, one small, reliable circulator takes the place of all these components. The Taco LOFlo System automatically provides only the flow temperature of water needed to satisfy the zone load at any given time.