Flex-Hose Pumpsaver from N.H. Yates

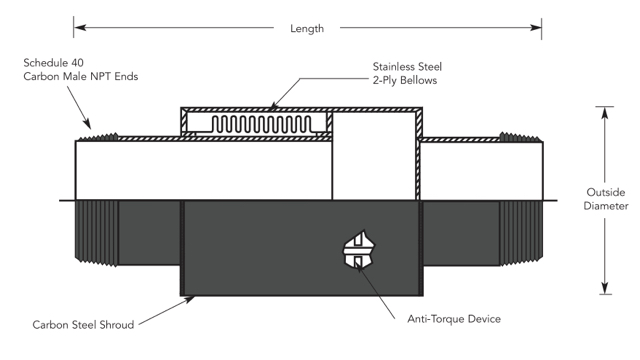

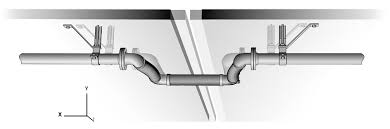

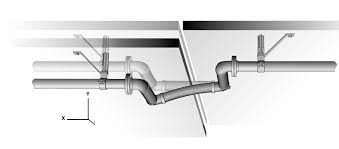

Many engineers and contractors use pump savers to prevent damage to pumps caused by piping stress that can shorten the life of the pump and its components. Rather than allowing hazardous movements and fluctuations, pump saver connectors absorb vibrations, accommodate for misalignments, and reduce the overall noise of pumping systems. The Flex-Hose Pumpsaver is the only one on the market that utilizes a closed pitch hose which makes for an unusually flexible, yet sturdy connection. This closed pitch construction saves installers during installation when aligning the piping system. In addition, the Pumpsaver’s innovative design saves many headaches for engineers during the design process.

Why Choose the Flex-Hose Pumpsaver?

At Flex-Hose Co., safety and performance are at the heart of everything they design. Each Pumpsaver produced by Flex-Hose Co. is made using the highest quality materials and manufactured under the strictest standards. In fact, Flex-Hose Co. only employes welders that are ASME Section IX certified to perform the complicated welds that are necessary to make the Pumpsaver. This attention to detail means that the Flex-Hose Pumpsaver will never come from the factory with any raw, jagged, or sharp edges which unfortunately are the industry norm. Instead, each Pumpsaver comes from the factory fit for a smooth transition at the first convolution flange. After completion, each Pumpsaver must pass a pressure test before they are sent to market. The Pumpsaver is available in stainless steels or bronze and is available in sizes 1/2 inch to 14 inches in diameter. Finally, the Pumpsaver is designed to be pressure tested up to 1.5X the maximum rated working pressure and are manufactured with a 4:1 safety factor. This compact design means you’ll save valuable space.