Commercial High-Purity Water Systems from N.H. Yates

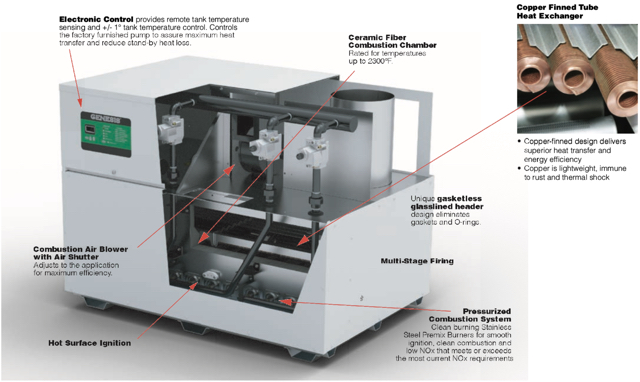

At N.H. Yates, we are proud to be a manufacturer’s for all of the fine products that Water Control Corp. offers. However, in this article, we are going to talk specifically about Water Control Corp.’s Commercial High-Purity Water Systems. As many of our satisfied customers are aware, Water Control Corp. has over 45 years of experience working with specialty water systems and therefore understand exactly what it takes to build your system and keep it running. From the initial water testing to 3D design, spec-writing and on-site commissioning, the experienced technicians at Water Control Corp. have what it takes to ensure that every detail of your product is addressed. These systems are high-purity water made simple!

All Commercial High-Purity Water Systems Include:

- Pre-Treatment:

- Temperature regulation

- Backflow prevention

- Softening

- Chemical feed

- Chlorine removal

- TOC reduction

- Production:

- 100-200,000 GPD systems

- Nanofiltration and De-Sal options

- Concentrate recycle

- Low energy and high output membrane options

- DI polishing

- Storage:

- 20-10,000 gallon tanks

- Hydropneumatic tank options

- Standard and core-bottom

- Air filtration

- HDPE and Polypropylene

- Delivery:

- Variable speed and DOL pumps

- Loop pressure controls

- UV treatment

- Sub-micron filtration

- Redundant pump options

- Controls:

- Standard and PLC/touchscreen panels

- NEMA options

- Single point electrical

conncections - BAS system integration

Water Control Corp. can build a packaged, turnkey solution to virtually any water treatment issue. This includes softening, filtration, high-purity water RO/DI, commercial rainwater harvesting systems, and more. N.H. Yates and the people at Water Control Corp.’s team of in-house professionals are here to support you through the entire process, from conception or commissioning, to service and every day